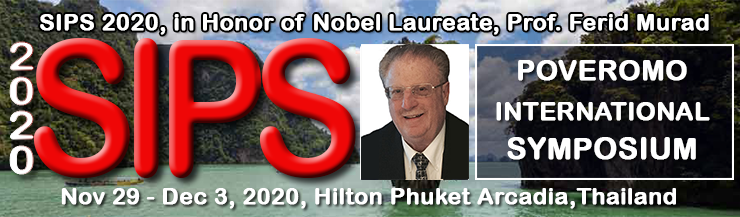

POVEROMO INTERNATIONAL SYMPOSIUM

On Sustainable Iron and Steel Making (8th Intl. Symp.)

Bio | CV | Publications

This major symposium is in honor of the distinguished work and lifetime achievements of Dr. Joseph J Poveromo. Dr. Poveromo is a well-known figure for his impact on ironmaking and ironmaking and steelmaking raw materials including blast furnace burden and gas distribution, development of fluxed iron ore pellets, utilization of iron ore concentrates in sintering, evaluating the impact of coal and coke properties on ironmaking processes, improvement of direct reduction grade pellets, advancement of natural gas utilization in ironmaking processes, promotion of iron ore based metallics in electric furnace steelmaking and analysis of economics of alternative ironmaking processes. He has dedicated himself to research, development and continuing education, starting with his collaboration with Prof. Julian Szekely at the State University of New York at Buffalo (SUNYAB), Center for Process Metallurgy, continuing at the Homer Research Labs of Bethlehem Steel, then serving as Technical Director, International with Quebec Cartier Mining Company and since 2008 as an independent consultant: Raw Materials & Ironmaking Global Consulting. His continuing education activities have been through the AIME Iron & Steel Society (now AIST, Association of Iron & Steel Technology), SME (Society of Mining Engineers) and McMaster University, Canada. He has authored book chapters on iron ore processing and products and books on the markets for metallurgical coke and ironmaking/steelmaking slags, and has made over 150 presentations and publications in national and international venues.

Throughout his career, his activity has impacted various fields, such as:

- Blast furnace fluid dynamics – his first research field at SUNYAB covered blast furnace fluid dynamics, where along with his advisor, Prof. Julian Szekely, he developed relationships to predict raceway and combustion zone penetration, shape, etc, as a function of blast conditions, coke properties, etc; they also were one of pioneers in using vectorial forms of the conservation equations to predict gas streamlines in packed beds such as the blast furnace stack region. These efforts culminated in a series of publications in refereed journals.

- Blast furnace raw material charging practices – he extended his University research into the real world at the Homer Research Labs where he utilized 1:18 scale physical models of blast furnace charging systems and stack region, utilizing scaled raw materials, based on similarity criteria, to develop improved charging practices. These improved charging practices contributed to increased productivity and reduced fuel rates at Bethlehem Steel’s two bell top furnaces. His publications of these results were recognized with the Iron & Steel Society Process Technology Division John Chipman Award in 1984.

- Blast furnace fluxed pellet development – he was part of a North America steel industry working group that proposed and conducted successful trials of newly developed fluxed pellets at Dofasco Steel in Canada; he later led an effort at Bethlehem Steel and Iron Ore Company of Canada to develop, test and utilize fluxed pellets. The adoption of fluxed pellets across North America led to process benefits (productivity, coke rate, lining life) with 100 % pellet operations while enabling the shutdown of older, small sintering plants with attendant environmental benefits. These and other accomplishments contributed to his receiving the AIME J. E. Johnson, Jr Award for outstanding ironmaking engineer under the age of 40

- Iron ore pellet chemistry improvements – within his time at Bethlehem Steel and later at Quebec Cartier Mining Company, he played a lead role in improving pellet quality by proposing flow sheet changes (fine screens, etc) to reduce SiO2 content to reduce blast furnace slag volume. He also modified fluxed pellet chemistry specs to increase CaO/SiO2 ratio to improve pellet strength and low temperature breakdown; he later proposed comparable changes to global pellet operations in Russia, Mexico and elsewhere.

- Improved DR grade pellet quality development – at Quebec Cartier Mining Company (QCM) he coordinated a working group to elevate QCM’s DR grade pellets to world class status whereby these pellets have been supplied to Midrex direct reduction modules in 5 continents. Improvements were made in reduction of pellet SiO2 level, increased reducibility and reduction of sticking tendency. He represented QCM in the IIMA (International Iron Metallics Association) and was later elected as a Fellow and Special Member of IIMA.

- Advancing Utilization of Iron Ore Concentrates in Sintering and Alternative Ironmaking Operations – iron ore concentrates are produced mainly by upgrading of lower grade ores to produce fine sized particles with excellent chemistry; Dr. Poveromo developed methods and promoted increased use of such concentrates in sinter plants in the USA and elsewhere globally and also in the Iron Dynamics Inc rotary hearth/submerged arc furnace hot metal process (to feed EAF’s). He also advanced the use of hematite concentrates produced from reclaimed iron ore tailings in Minnesota for use in pelletizing in Mexico.

- Blast furnace process control, optimization and lining life extension – in his experience at Bethlehem Steel and later consulting globally in BF operations in Argentina, Brazil, Canada, Belgium, Italy, Russia, China, etc, he proposed and implemented improved operating practices, computer data acquisition & control systems, refractory and cooling system improvements, burdening schemes; in 1998 he received the Iron & Steel Society T. L. Joseph Award for lifetime achievements in ironmaking technology and practices.

- Reducing reductant and energy consumption in ironmaking – his efforts here included: advancing granulated coal injection at Bethlehem Steel by proposing a research program with Federal government funding to demonstrate granulated coal injection using North American coals, advocating “co-injection” practices whereby coal and natural gas are injected together, quantifying the benefits of improved coking coals and coke properties on blast furnace energy and reductant consumption, modeling the use of H2 as an injectant, developing the Fuel Injection lecture at the McMaster U Blast Furnace Ironmaking Course and lecturing on the “Role of Coke in the Blast Furnace” at the McMaster U Cokemaking Course.

- Advancing use of ore-based metallics in EAF Steelmaking – through the IIMA and his consulting activities, he has promoted the use of ore based metallics(DRI, direct reduced iron, HBI, hot briquetted iron and merchant pig iron in EAF steelmaking; these have included demonstrating the value-in-use of these materials, evaluating processes and projects to produce DRI, HBI and pig iron, expanding the production of DR grade pellets and utilization of lump ore and making presentations at international venues on ore based metallics process economics.

- Professional society and educational activities – Dr. Poveromo is a Distinguished Member of AIST as he was elected by the predecessor Iron & Steel Society (ISS) in 1995 where his citation noted long standing contributions to ISS Continuing Education Courses. He was the only person to serve as Chair of two (of four) Divisions of ISS: Process Technology and Ironmaking and continues to serve on the AIST Ironmaking and Direct Reduction Ironmaking (DRI) Committees. He was a founding member of the AIST DRI Committee. Dr. Poveromo has presented seminars and short courses at SME Meetings in Duluth, Mn and globally at conference venues in Canada, Argentina, Brazil, Australia and South Africa. He lectures bi-annually at the McMaster U Cokemaking and Blast Furnace Courses and also has served on a number of Ph.D. dissertation committees globally. He is also an active member of SME (Society of Mining Engineers) and co-authored chapters on Agglomeration and Iron Ore Beneficiation in SME texts.

Dr. Poveromo's honors and distinguished activity may be summarized as follows:

- Organizing Chairman – AIST Advanced Technology Symposia: Scrap Supplements & Alternative Ironmaking: Baltimore, Oct. 2004, Nov. 2008, and Oct. 2012

- Plenary Lecturer – 5th International Congress on Science and Technology of Ironmaking, Rio de Janiero, Brazil, Oct. 2012

- Special Member – IIMA (International Iron Metallics Assoc., formerly HBIA (Hot Briquetted Iron Assoc., March 2009

- Honorary Chairman, COREM Pelletizing Symposium, Quebec City, June 2008

- Plenary Lecturer – 4th International Congress on Science and Technology of Ironmaking, Osaka, Japan, Nov. 2006

- Keynote Paper, "The Evolution of Ironmaking", Sohn International Symposium on Advanced Processing of Metals, San Diego, Aug. 2006

- Keynote Paper "Raw Material Challenges for Blast Furnace and Direct Reduction Ironmaking", 5th IAS Ironmaking Conference, November 2005, San Nicolas, Argentina

- John Chipman Award, 2000, Process Technology Division, Iron & Steel Society, "for best paper in ISS publications"

- T. L. Joseph Award, ISS, 1998, for sustained contributions to ironmaking technology

- Organizing Chair, International Program Committee: Second International Congress on Science and Technology of Ironmaking, Toronto, Canada, Mar. 1998

- Invited Keynote Lecture, 27th Annual McMaster Symposium on Iron and Steelmaking, "Use of Models to Optimize Blast Furnace Operations", May 1999

- Invited Lecturer - Symposium for 250th Anniversary of Jernkontoret, Stockholm, Sweden, June, 1997

- Distinguished Member of Iron & Steel Society, AIME, 1994 -

- Keynote Lecturer - First International Congress on Science and Technology of Ironmaking, Sendai, Japan, June 1994

- John Farrell Award, 1986, for service as Chairman of Process Technology, Div. and Director of Iron & Steel Society

- John Chipman Award, 1984, Process Technology Division, Iron & Steel Society, "for best paper in ISS publications"

- J. E. Johnson Award, 1981, Ironmaking Division, Iron & Steel Society, "for improved furnace charging methods"

- Through these activities, he has contributed significantly to the advancement of raw materials and ironmaking process technology, engineering and economics.

This symposium is organized on the occasion of Dr. Poveromo's 50 year technical anniversary. Reflecting on his outstanding industrial, academic and professional society activity, this international symposium will feature plenary, keynote and invited lectures on scientific and technological raw materials, ironmaking and steelmaking topics, such as mineral processing, pelletizing, sintering, ironmaking and steelmaking processes, environmental control, CO2 process reduction; not only conventional but also novel processes or ideas are welcome.

ROUND TABLE DISCUSSIONS

A round table discussion open to everyone interested will be organized at a specific date and time during the symposium. It will be a platform for high level representatives of various industries, technologies, and academic disciplines to freely discuss and debate all topics of this symposium, and identify positive and efficient pathways towards sustainability in industrial practices, technologies, and research.

You are cordially invited to actively participate in this symposium by submitting and presenting a paper, or by attending the round table. We look forward to meeting you in Phuket, December 2020.

To download Flyer, click on the icon:

Click here to see the detailed scope and topics.

Click here to see the General Author Invitation

Click here to see the detailed scope and topics.

Click here to see the General Author Invitation

CHAIRS

Florian Kongoli

FLOGEN Technologies

Canada

[Bio]