Fray International Sustainability Award

About Award Winners

Politics |

Corporations |

Academia |

Research Institutions

Dr. Norman Lotter

Dr. Lotter is a well-known figure for his strong impact on metallurgical testing and flowsheet development at several scales. This work is especially well known in the area of platinum group metal ores and base metal ores. For the past 30 years he has dedicated himself to the development and application of new protocols to measure and prove small performance differences in grade and recovery arising from improved processing treatments. He has based all of his development work on cross-disciplinary methods and fundamental principles. Since 1994, he has published over 39 papers detailing the development of these methods, and with case studies in which performance improvements were found at laboratory scale and demonstrated at operations scale. He has established an outstanding record of introducing new methodologies and technologies for the betterment of Process Mineralogy worldwide. His work has been recognised by both his peers in Canada and around the Process Mineralogy world. When reviewed in its entirety it is clear that his professional achievements have made the Mineral Processing industry much more productive in metal recovery and operational efficiency. He has had, and continues to have, a remarkable record of success in bringing new applied technologies to Mineral Processing operations. His singular achievement has been to improve the performance of mills by working back to the ore body - either being mined or available from drill core - and integrating the information gleaned from the mineralogy into performance improvements in areas such as optimal crushing, grinding, and flotation for grade and recovery. All of this is done with high statistical confidence. The ability to use his fundamental research and integrate it into practical tools has become a hallmark of his work. He has earned the respect of the Mineral Processing community worldwide. His contributions were recognised in 2010 when he was appointed as a CIM Distinguished Lecturer, and the Canadian Mineral Processors conference organisers asked him to practically demonstrate his complex sampling theories in short courses. In addition, his relations with mill operators, university collaborators and his fellow engineers in mineral process development have led to a very high level of mutual respect and trust.

Dr. Lotter has also trained and mentored many young engineers in his career. He is a supporter of inter-disciplinary training, where synergies in project work are to be found.

Some of his career highlights in method development have been:- The development of high-confidence flotation testing at Rustenburg Platinum Mines Limited, South Africa. This protocol enabled flotation tests on samples of platinum-bearing ore to become reproducible, so that small performance differences could be identified and measured. The first prototype of this model was published with the South African Mine Metallurgical Managers Association in 1994, and was presented with a gold award for his contribution to best practice. It was later presented after further improvements in its final form to the SME in Denver at their 1995 meeting. This model was put to work for the operating concentrators of Rustenburg Platinum Mines Limited, and successfully focussed on improved grinding and flotation circuit layout and reagent strategies. This model was also used during the sampling and testwork for the design of the Potgietersrust Platinum concentrator, the first Platreef ore treatment operation in the world, which commissioned successfully with designed grade and recovery.

- The development of statistical benchmark surveying at Falconbridge Limited, Canada. This protocol enabled the surveying of operating concentrators to deliver representative sample suites to the mineralogy laboratory for measurement. This work was presented to the MEI conference Nickel '05 in Cape Town, South Africa, as well as to the Canadian Mineral Processors conference in Ottawa, Canada, and was published in the Minerals Engineering journal in 2007.

- Together with his team, the development of Virtual Flowsheeting from mineralogical data using samples of drill-core. This enabled the more fundamental arrangement of grinding strategies ahead of any flotation testing, as well as the identification of any problematic minerals.

- Together with Prof. Dee Bradshaw, University of Cape Town, South Africa, the development of a theory of formulation of mixtures of collectors in sulphide flotation to deliver enhanced flotation performance from synergistic effects between different collector types, using semiconductor and electrochemistry theory.

- The significant reduction of arsenopyrite recovery to the antimony concentrate produced at the Consolidated Murchison Mine, South Africa, by diagnosing an incomplete liberation problem in the scavenger concentrate, and by arranging for this stream to be reground before further processing. This greatly reduced the arsenic grade in saleable antimony concentrate, and enabled the shutdown of an inverse flotation process that used to float the arsenopyrite to a disposal concentrate at the expense of antimony recovery (1978).

- Contributions to the project work for the Waterval Regrind and Scavenger Circuit at Rustenburg Platinum Mines Limited, South Africa, as a core team member. This retrofit was designed to improve mineral liberation and flotation plant capacity so as to increase platinum recovery. The project commissioned with designed performance (1986).

- The flowsheet development of the Potgietersrust Platinum project, South Africa. This was the first Platreef ore project to be commissioned in the world, and commissioned on designed grade and recovery (1994).

- Improvement of the metallurgical performance of the commissioned Raglan project in 1998, using flotation tests and surveying with mineralogical analysis to identify flowsheet improvement opportunities, which were successfully implemented (1998-2000).

- Flowsheet development work for the Montcalm project, North Ontario, in which the grade and recovery of treatable concentrate was estimated from testwork on drill-core. The project was successfully commissioned at designed performance within three months of startup (2004).

- The development and formulation of a mixed collector suite for Eland Platinum Mine, South Africa, together with co-workers, using laboratory scale flotation tests based on ore mineralogy, and the successful plant trial thereof, demonstrating accurate scaleup of grade and recovery gains from laboratory work (2011).

- Flowsheet development testwork for the Ivanhoe Kamoa copper project, Democratic Republic of the Congo, from drill core to Prefeasibility Study (2012).

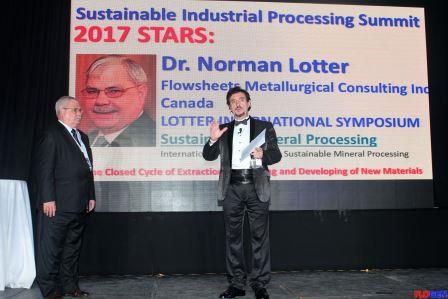

Dr. Norman Lotter, Receiving the Fray International Sustainability Award from Dr. Florian Kongoli at FLOGEN SIPS 2017

Dr. Florian Kongoli introducing Dr. Norman Lotter as a winner of the FLOGEN SIPS 2017 Fray International Sustainability Award

Norman Lotter delivering his acceptance speech, to Dr. Florian Kongoli, during the FLOGEN SIPS 2017 Fray International Sustainability Award ceremony

Dr. Norman Lotter, winner of FLOGEN SIPS 2017 Fray International Sustainability Award, in conversation with Dr. Florian Kongoli