Fray International Sustainability Award

About Award Winners

Politics |

Corporations |

Academia |

Research Institutions

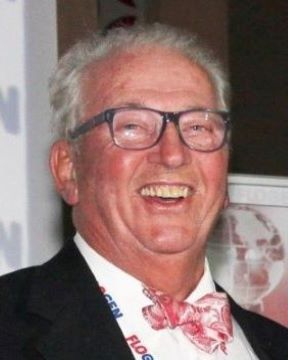

Prof. Heinrich W. Gudenau

Sustainable Iron Making

One of the most famous contemporary persons, who we all owe so much, is in the focus of this "2015-Sustainable Industrial Processing Summit & Exhibition": Mr. Heinrich-Wilhelm Gudenau from Aachen town in Germany. For several decades until nowadays, he is busy in development of both knowledge in iron and steel making and education of gifted people, feeling the same way.

All the time in responsible positions, he followed one clear goal: the sustainable development of iron and steel making. For him, sustainability means that we work in a careful way on our resources with high efficiency, so that our generation and all following generations will be able to produce their own iron and steel to fulfill their own demands. 'Iron making' means the application of hot reduction gases to iron ore that stone-like matter mined from the ground. The two essential reduction gases are carbon monoxide and hydrogen, and during the last thousands of years the carbon monoxide is the essential way of 2 choice. Though, Heinrich-Wilhelm Gudenau, who is called HeiWi {hai-vee} by his friends, dedicates his power to blast furnaces, direct reduction processes and coal gasification to make sure that those gases will be available also under critical conditions and will be applied in an efficient way. Special investigations on fluid dynamics in a period when computers of extended power like today were not available; underground gasification of coal in depth of more than 1000 m to produce the reduction gas in situ had ambitious goals, 30 years ago. The so-called Direct Reduction of iron ore to generate solid iron metal directly without melting and carbon pick up was a target, which brought him in direct contact with Willy Korf, a pioneer and business man in that field. After his death, his daughter, Astrid Korf-Wolman, initiated a Foundation with the help of Prof. Gudenau. This foundation grants the "WillyKorf-Award for Young Excellence", which is given annually in New York meetings to the best followers: for example, the awardee Dr. Paulo de Souza, who built the famous successful Mars Planet Exploration Rovers "Opportunity" and "Spirit" in a NASA's research team. Today, additionally, the foundation also grants the "Willy-Korf-Excellence-Lecture-Award", which has been awarded to international personalities; like Prof. Gunnar Still from ThyssenKrupp Company, Mrs. Prof. Dagmar Juchelkova from the Czech Ostrava University, and Prof. Yanping Bao from the University Science and Technology in Beijing. A pioneer of hydrogen application to iron ore reduction, Ludwig von Bogdandy, came in contact with Prof. Gudenau and one sustainable output of those meetings was the "Ludwigvon-Bogdandy-Award for Innovative Metallurgy" to support young powerful and busy metallurgists at Aachen University

Prof. Heinrich W. Gudenau, Receiving the Fray International Sustainability Award from Dr. Florian Kongoli at FLOGEN SIPS 2015